Laboratory EUV Sources

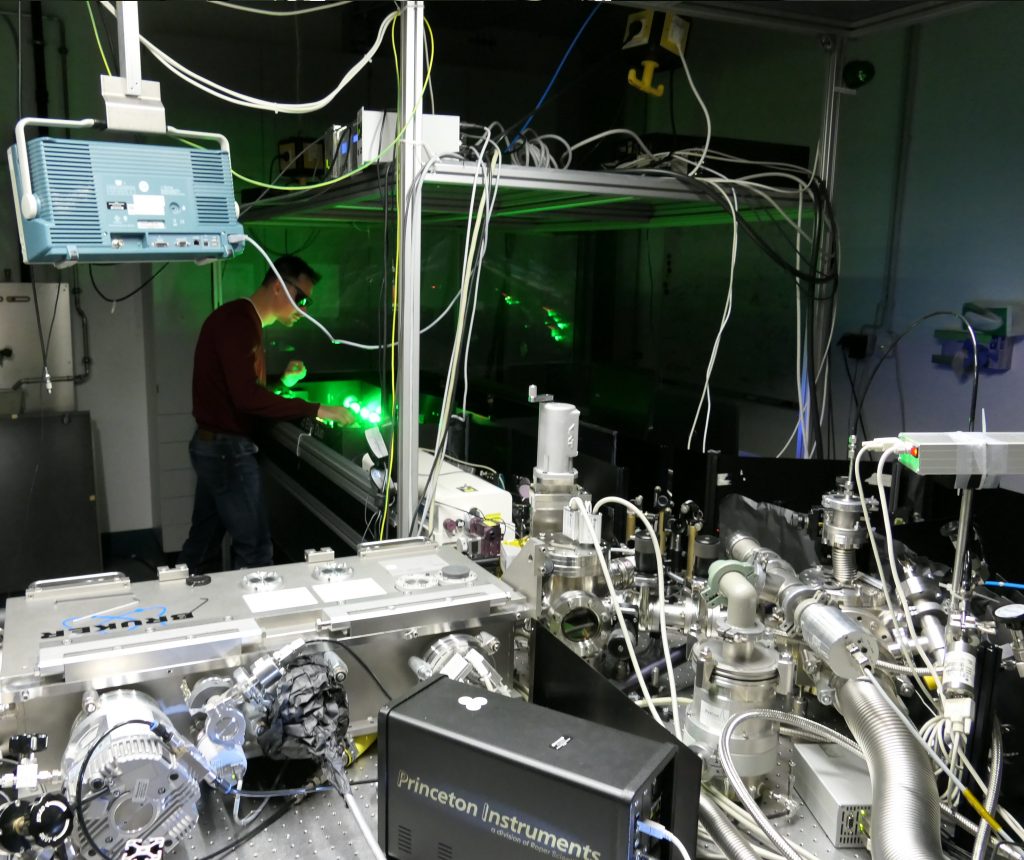

Wavelengths encompassing extreme ultraviolet (EUV) and soft x-rays are important for a wide range of applications, such as material research, lithography, and chemical analysis. Although these wavelengths can be produced in a synchrotron, these sources are typically limited in both time resolution and continual access. Laboratory based EUV/soft x-ray sources provide increased experimental flexibility, allowing for attosecond temporal resolution as well as continual access for more fundamental studies.

Laboratory tabletop EUV sources can be generated in two ways. The first is via a laser-pulse plasma, in which a metal target, typically tin, is ionised to form a plasma. This produces a broad beam of EUV wavelengths which can be used for lithography-based applications.

High-harmonic generation is the most common way to generate lab based EUV source due to its reliability and precision. It produces a range of coherent EUV – soft x-ray wavelengths that are spatially separated, offering experimental flexibility and optimization. High harmonic generation can produce EUV/soft x-ray sources at rapid speeds, allowing for research such as attosecond nonlinear optics, spin dynamics, and heat transport studies, all on the nanoscale.

Cameras for Laboratory Based EUV Sources

PI-MTE3

The PI-MTE3 is a fully in-vacuum CCD camera, with the ability for the cooling and electrical cables to also be within the vacuum chamber. This provides exceptional reliability and flexibility for camera placement within a vacuum chamber, ideal for a wide range of applications, in particular applications which rely on scattering or diffraction techniques.

The sensor within the PI-MTE3 is positioned at the base of the camera, allowing for direct detection of ultra-low incident angles, optimal for EUV/soft x-ray diffraction studies. The PI-MTE3 is also buttable, offering the advantage of a larger sensor area while providing space for the removal of the primary probe beam. The PI-MTE3 also has large format sensors, optimal for collecting the full scattering profile both at the center and at the edges.

The PI-MTE3 has low read noise and is liquid cooled for low dark current noise – vital for minimizing any noise-based artifacts. With 7-10x higher resolution than previous PI-MTE generations, the PI-MTE3 achieves 3 full fps at 2k x 2k resolution for faster readout times – optimal for measuring larger samples.

SOPHIA-XO

With peak quantum efficiency of >95% over a wide range of soft x-ray energies, the SOPHIA-XO provides high sensitivity for low light EUV/soft x-ray signals. The SOPHIA-XO is able to reach high frame rates with multiple port readouts, minimizing overall experimental time – essential for larger samples or frequent sample changes.

To ensure all signal is captured, the SOPHIA-XO comes with both 2k x 2k and 4k x 4k sensor options. These sensors allow for binning, combining the advantage of increased signal-to-noise ratio and increased frame rate. With low read noise and deep cooling to minimize dark current noise, the SOPHIA-XO allows for the detection of the faintest of EUV/soft x-ray signals while minimizing any noise-based artifacts.