Professor Rajesh N. Davé

New Jersey Institute of Technology (NJIT), USA

Background

Prof. Davé’s research group at NJIT focuses on the creation of advanced particulate materials and products through particle engineering. As the founding director of the New Jersey Center for Engineered Particulates in the Otto H. York Department of Chemical and Materials Engineering, Dr. Davé’s research and innovations improve particle properties for applications in the pharmaceutical, food, electronics, and energy industries. In addition to engineered particulates, he and his colleagues concentrate on pattern recognition and cluster analysis.

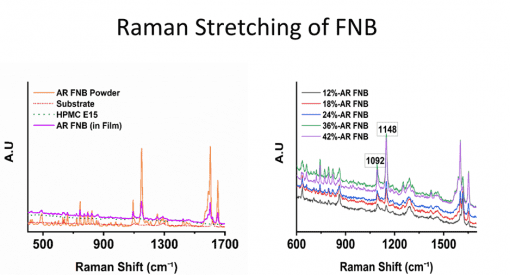

Figure 1: Raman lines at 1092 cm-1 and 1148 cm-1 appeared from the fenofibrate (FNB) strip films and pure FNB powder due to presence of FNB, whereas no obvious Raman line appeared due to substrate. Data courtesy of Guluzar Gorkem Buyukgoz, Scott Quirie, Matheus Montarroyos, and Rajesh N. Davé (NJIT).

Challenge

One of the research projects that Dr. Davé’s research group is analyzing, via Raman spectroscopy, a novel 3D printed drug development product with a strip-film format. In order to improve product quality through process design, the use of various process analytical technology (PAT) tools is required to help provide in-line and real-time process information that allows monitoring of processing variables and prediction of product quality. When properly conceived and applied, this approach offers many benefits compared to the time-consuming, expensive, and inefficient off-line testing traditionally employed to ensure strict pharmaceutical product specifications are met.

Researchers working with Dr. Davé at NJIT identified three main goals for the aforementioned project: (1) establishing the feasibility of using Raman spectroscopy to monitor the concentration of poorly water-soluble active pharmaceutical ingredients, or APIs, in a strip film, in-line; (2) minimizing the variations that may cause irregularities in spectra; and (3) developing prediction models during in-line measurement from strip film loaded with API.

FERGIE provides the reliable in-line performance this type of work demands

Solution

A FERGIE system (previous version of the IsoPlane 81) was chosen for the Raman spectroscopy and real-time monitoring required to assess the critical quality attributes of the strip films (see Figures 1 and 2). The FERGIE was well suited for work with various drug delivery platforms, including polymer films and 3D printed tablets.

The researchers report that all three main objectives of the project were satisfied, including the successful application of the PAT tool for monitoring the strip film manufacturing process with respect to in-line quantification of API concentration along with the Raman spectroscopy. Partial least squares (PLS) models were built with in-line measurement of Raman spectroscopy and each R2 (validation metric) was found to be ≥0.99.