Breakthrough Technology in BLAZE® Scientific CCD Cameras Greatly Enhances Near-Infrared Quantum Efficiency and Enables Superior, Quantitative, Spectroscopic Measurements

Overview

Featuring two revolutionary back-illuminated deep-depletion sensors, Teledyne Princeton Instruments BLAZE cameras for spectroscopy provide the highest near-infrared quantum efficiency, fastest spectral rates, and deepest thermoelectric cooling available in a CCD platform. Lower thermally generated dark noise, combined with the use of low-read-noise electronics, raises the signal-to-noise ratio and further improves sensitivity.

Applications for BLAZE cameras include nanotechnology, 2D materials, carbon materials, biosensing, and life science. These next-generation cameras deliver the highest performance for scientists using measurement techniques like Raman, photoluminescence, and fluorescence spectroscopy, as well as micro-spectroscopy and pump-probe spectroscopy.

Introduction

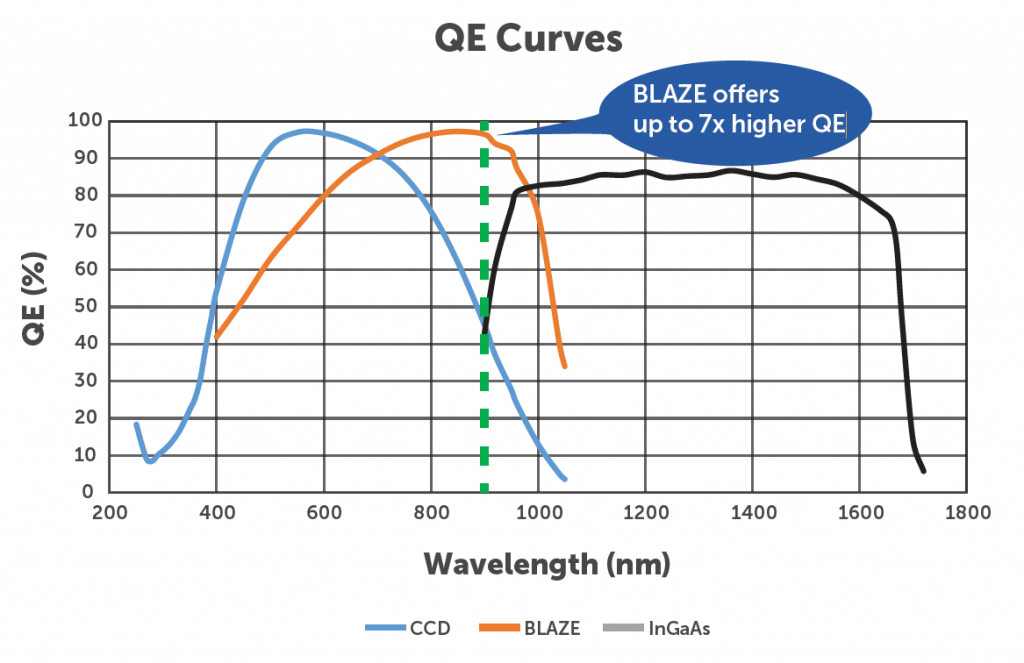

Detection systems based on various back-illuminated CCD architectures are preferred for most spectroscopy applications as this reliable sensor technology is able to offer the highest available quantum efficiency over the entire UV-VIS-NIR wavelength range — from less than 200 nm to 1.1 μm.

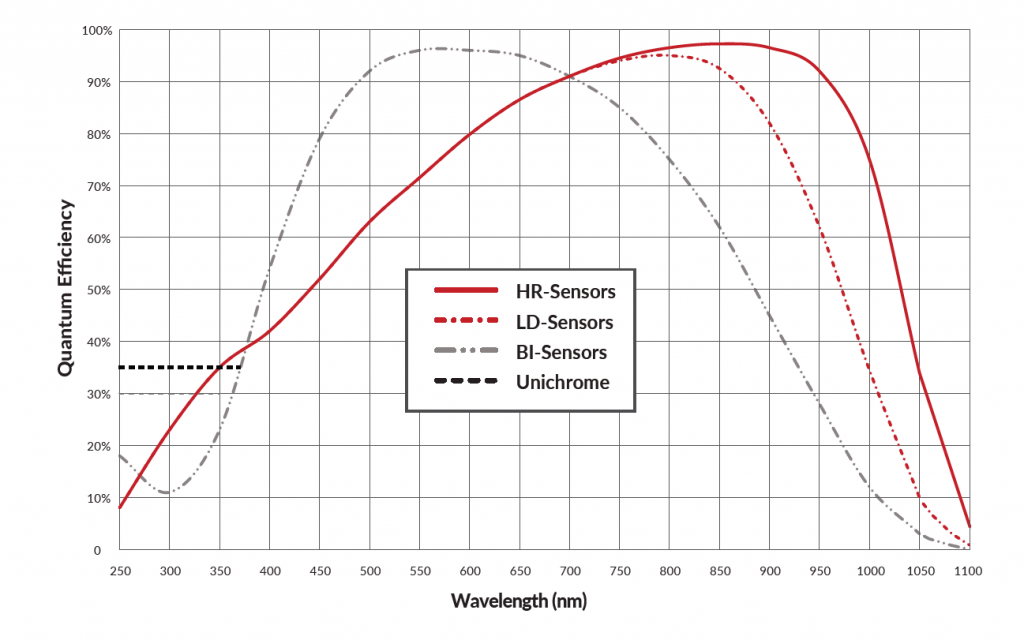

Standard back-illuminated sensors are manufactured by chemically etching and polishing a silicon wafer down to a thickness of only 13 μm. When illuminated from the back of the sensor, nearly 100% of incoming light can be detected since it strikes the epitaxial silicon layer without having to pass through the polysilicon gates located at the device’s front.

Back-illuminated deep-depletion CCDs use a thicker silicon depletion region (~40 μm) to compensate for the longer absorption lengths necessitated by longer wavelengths. In the NIR, quantum efficiency increases as the thickness of the depletion region increases. Therefore, compared to their standard back-illuminated counterparts, back-illuminated deep-depletion CCDs have superior efficiency in the NIR.

However, it is important to note that all silicon-based CCDs are fundamentally incapable of detecting wavelengths longer than 1.1 μm. Teledyne Princeton Instruments also offers InGaAs detectors in either linear or 2D array formats. These devices are photosensitive in the

wavelength range from ~850 nm to 1.7 μm (2.2 μm on extended-range devices), though one should realize that InGaAs, a III-V compound semiconductor, does exhibit higher dark current than silicon and such systems usually rely on liquid nitrogen cooling to improve signal-to noise ratios.

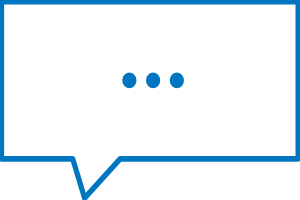

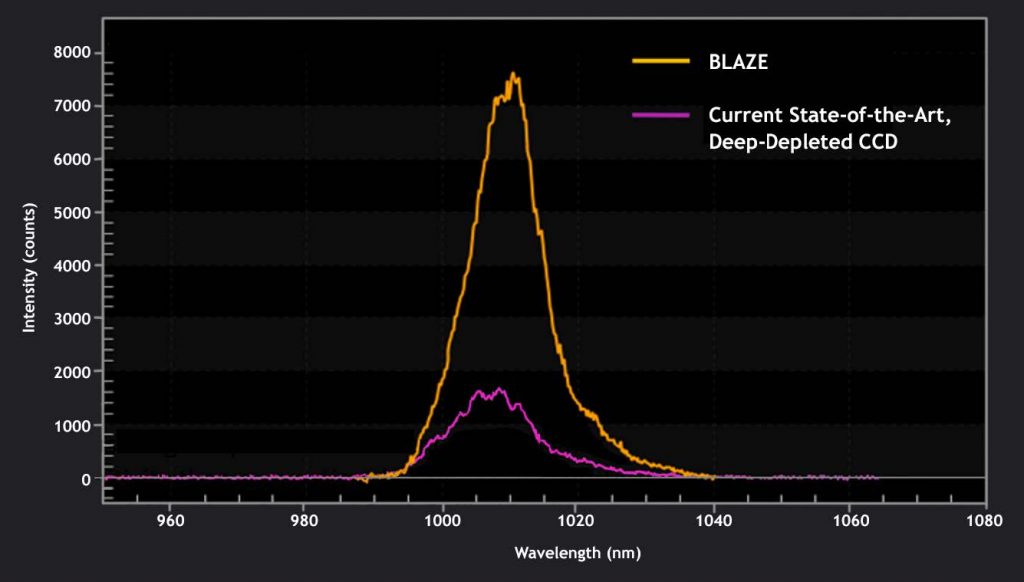

Until the introduction of BLAZE, a severe performance limitation in the wavelength range from 800 nm to 1.0 μm — colloquially known as the “Valley of Death” — plagued spectroscopists no matter which type of CCD, InGaAs, CMOS, PMT, or solid-state single-point detector they chose to use for their work. BLAZE cameras solve the longstanding problem by providing much higher quantum efficiency in this special wavelength band (see Figure 1).

New Proprietary Sensor Technology

BLAZE spectroscopy cameras are based on a revolutionary new class of back-illuminated deep-depletion CCD sensors. In addition to providing 3x to 7x greater sensitivity between 800 nm and 1100 nm than the previously best detectors, BLAZE sensors deliver 95% peak quantum efficiency at 900 nm (see Figure 2). The new sensors are offered in either 1340×100 or 1340×400 array formats with 20 μm pixels.

Proprietary BLAZE HR-Sensors (see Figure 3) are “super-deep-depletion” CCDs manufactured from high-resistivity bulk silicon in order to yield the highest near-infrared quantum efficiency of any silicon device. The silicon depletion region of each HR-Sensor is almost 4x thicker than that of a conventional deep-depletion (NIR-sensitive) CCD, affording quantum efficiency up to 7x greater at 1 μm than the best other deep-depletion sensors.

Spatial resolution for HR-Sensors is optimized by applying a bias voltage, resulting in a “fully depleted” silicon region with no diffusion of charge. The bias voltage generates an electric field that pushes the charge toward the correct pixels and does not allow charge to migrate to adjacent pixels.

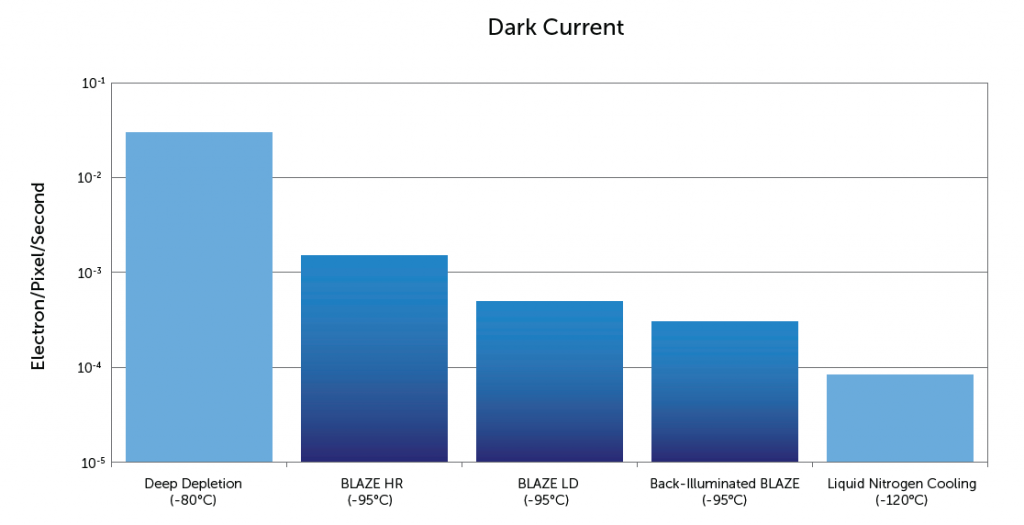

Proprietary BLAZE LD-Sensors are back-illuminated deep-depletion devices designed for high sensitivity and exceptionally low dark current (see Figure 4). These devices run in inverted mode, which applies negative voltages to the imaging phases and drives each phase into inversion. The resultant negative charge attracts holes that fill the surface states, suppressing dark current generation in the states. The use of inverted mode and deep thermoelectric cooling reduces dark current to 0.0005 e-/pix/sec (typical), making LD-Sensors ideal for experiments that require long integration times.

Demonstrably Better Performance

To demonstrate the performance of the BLAZE HR-Sensor, we designed three experiments measuring the device’s increased sensitivity compared to current state-of-the-art detection.

Experiment #1

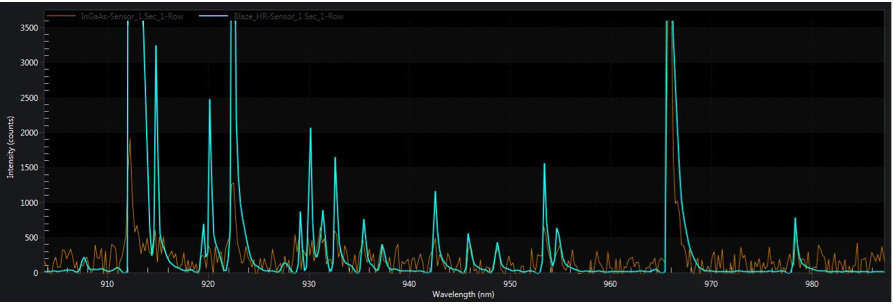

We acquired atomic lamp emission from 880 nm to 1.0 μm with both a thermoelectrically cooled BLAZE HR-Sensor as well as an LN-cooled InGaAs array for comparison. Figure 5 displays the spectra, which were collected under identical conditions (i.e., same spectrograph, grating, and light source). The signal-to-noise ratio achieved was significantly higher using the BLAZE HR-Sensor.

Experiment #2

In the second experiment, we measured the photoluminescence of indocyanine green (IcG) in the same wavelength range as our first experiment. Figure 6 shows the setup used in the second experiment. By focusing the output of an excitation light source via a lens onto a cuvette containing the IcG sample, photoluminescence (PL) emission was collected and collimated with another lens oriented 90° from the excitation beam. Passing through a filter, the collimated beam was focused onto the entrance slit of a spectrograph equipped with a pair of detectors: (1) a thermoelectrically cooled BLAZE camera configured with an HR-Sensor and (2) an LN-cooled linear InGaAs array. A moveable beam-diverter mirror enabled the dispersed PL emission to be directed to either of the two detectors.

BLAZE HR-Sensor and an LN-cooled linear InGaAs array.

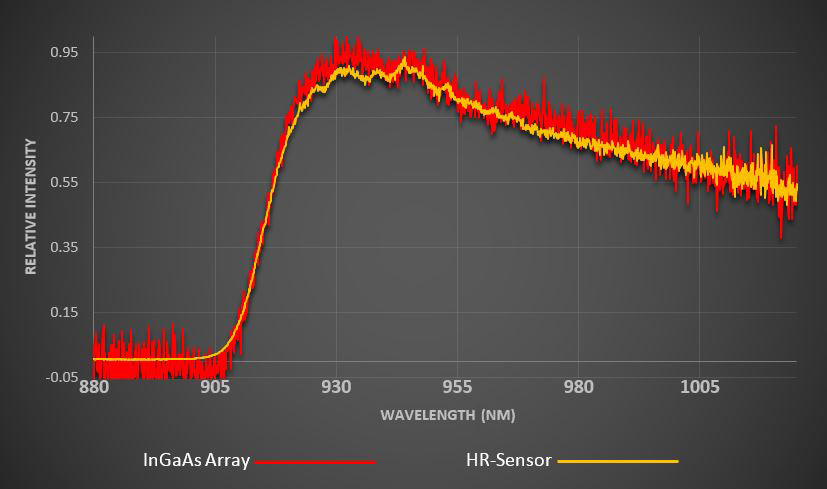

Teledyne Princeton Instruments LightField® software was utilized to control operation of the system as well as acquisition of data. PL spectra were acquired using both cameras, allowing the integration time to be adjusted to yield the same relative intensity. Integration time was 15 seconds for the HR-Sensor and 100 seconds for the InGaAs array. To eliminate unwanted instrumental influences on the spectral data, intensity calibration was performed using the Teledyne Princeton Instruments IntelliCal® calibration system and a NIST-traceable quartz tungsten halogen (QTH) lamp.

Figure 7 shows good correlation between the spectra produced by each of the cameras. However, the HR-Sensor was able to provide ~6.6x greater sensitivity while producing a spectrum with significantly lower background noise. Therefore, new BLAZE cameras will allow researchers to detect ultralow concentrations of IcG and perform more complex functional spectroscopy inside tissue.

Experiment #3

Figure 8 shows the Raman spectrum of cyclohexane (from ~150 to 3000 cm-1) acquired with the BLAZE HR-Sensor. A 500 mW, 785 nm laser was used to generate Raman scatter within the cyclohexane sample. A lens collected and collimated the Raman scatter, which then passed through a Rayleigh filter to suppress the laser radiation. A spectrograph dispersed the Raman scatter onto the HR-Sensor for detection and analysis. The HR-Sensor’s superior quantum efficiency enabled rapid detection of the Raman signal out to 3000 cm-1 (1026 nm).

Speed That Meets All Needs

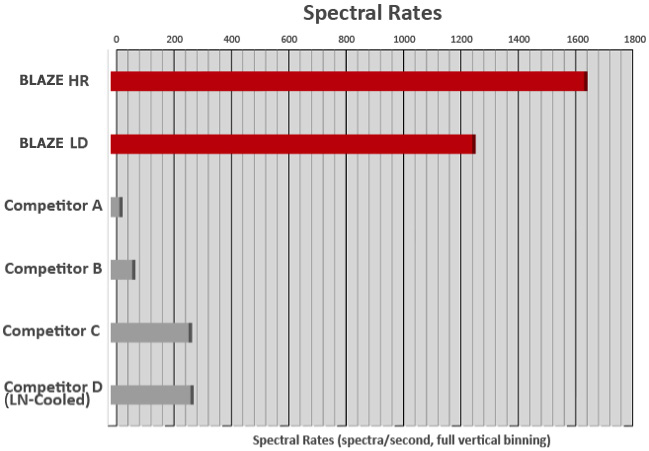

The new BLAZE platform incorporates the fastest ADC speeds available in a CCD camera (see Figure 9). The LD camera models can run with dual 10 MHz readout ports, while the HR cameras feature dual 16 MHz readout ports. This enables unprecedented spectral rates of more than 1600 spectra/second with full vertical binning and up to 215 kHz when operated in kinetics mode — critical for synchronizing with ultrafast lasers in time-resolved studies such as coherent anti-Stokes Raman spectroscopy (CARS), tip-enhanced Raman spectroscopy (TERS), and biological in vivo Raman spectroscopy.

The unique design of BLAZE sensors also allows the cameras to utilize Teledyne Princeton Instruments’ exclusive SeNsR feature: on-chip bi-directional clocking and accumulation of signal. With SeNsR, the charge (i.e., signal) can be shifted on the CCD without reading out the data. This innovation lets BLAZE cameras operate in a semi-lock-in mode during pump-probe experiments to boost signal-to-noise ratio and improve low-light-level detection.

Deep Thermoelectric Cooling

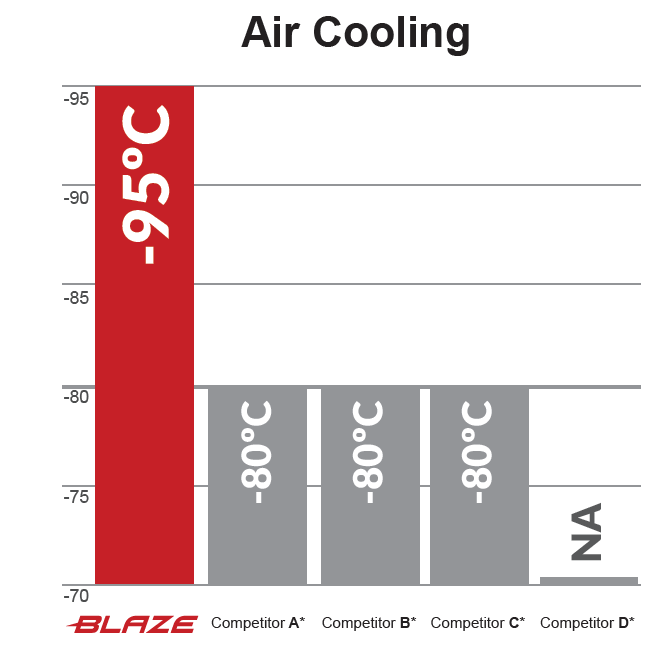

All BLAZE cameras feature Teledyne Princeton Instruments’ proprietary ArcTecTM technology, deep thermoelectric cooling that allows operation to -95°C in air (see Figure 10), without chillers or liquid assist, for low-dark-current performance.

ArcTec uses custom-designed Peltier devices, advanced multi-stage thermoelectric cooling, and permanent all-metal ultra-high-vacuum seals to achieve unprecedented cooling performance for spectroscopic CCDs. System reliability is backed by a lifetime vacuum guarantee. With ArcTec, BLAZE cameras can even provide condensation-free TRUE -100°C cooling by utilizing near-room-temperature (i.e., +20°C) liquid assist.

One should be aware that typically when manufacturers claim -100°C operation it requires use of +10°C chilled liquid, which creates the very real possibility of harmful condensation forming inside the cameras that can ultimately compromise the ability to cool their sensors.

The colder CCD temperatures attained by BLAZE cameras result in lower dark current, allowing longer exposure times and superior low-light detection capabilities.

Smart Spectroscopy Software

Seamless integration of BLAZE with LightField software (see Figure 11) allows complete system control, data acquisition, and processing of spectral data. This powerful 64-bit package runs on Microsoft® Windows® 10 and comes with integrated LabVIEW® (National Instruments) and MATLAB® (MathWorks) support. For multi-user facilities, LightField can remember each user’s experimental configuration.

LightField’s key features include dependable data integrity via automatic saving to disk, time stamping, and retention of both raw and corrected data; the integration of new SeNsR technology for lock-in and pump-probe experiments; LightField Math, which allows simple and complex math functions to be applied to live or stored data while also offering an easy-to-use editor to create formulas; easy exporting to many file formats, including TIFF, FITS, ASCII, AVI, IGOR, and Origin; and live data processing operations that provide real-time evaluation of incoming data to optimize experimental parameters.

Myriad Applications

BLAZE cameras are well suited for a wide variety of spectroscopic techniques, including Raman spectroscopy, photoluminescence, fluorescence, emission, absorption, micro-spectroscopy (e.g., micro-Raman and micro-photoluminescence), and hyperspectral imaging. BLAZE applications can involve nanoparticles, nanowires, carbon nanotubes, medical/biomedical samples, semiconductors, pharmaceuticals, and many other materials. Below are just three examples of the BLAZE platform’s impressive utility.

Application Example #1 – Life Science / Coherent Anti-Stokes Raman Scattering

Nonlinear spectroscopy using coherent anti-Stokes Raman scattering (CARS) and femtosecond laser pulses is a powerful tool for chemical analysis and biological imaging. Multiplex CARS is an important technique due to its ultra-broadband spectral coverage of ~3000 cm−1. Optimization of both the peak intensity and the repetition rate of the laser source is considered a key factor for multiplex CARS.

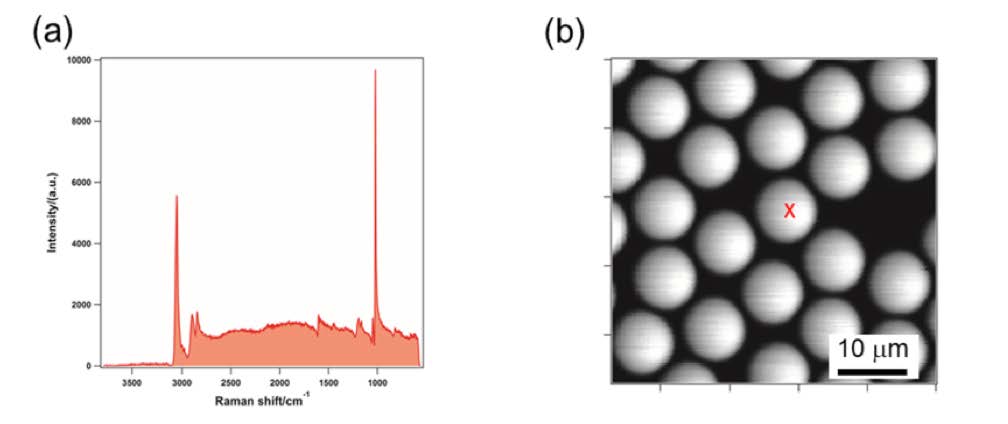

Recently, Prof. Hideaki Kano from the University of Tsukuba in Japan reported that clear molecular fingerprinting was achieved for living HeLa cells at different phases in the cell cycle (see Figure 12). Dr. Kano and his colleagues leverage the improved sensitivity and spectral rates of the BLAZE camera platform combined with a high-throughput Teledyne Princeton Instruments LS-785 spectrograph. They were able to significantly increase spectral quality while acquiring data at one of the fastest acquisition speeds for ultra-broadband CARS to date. LightField reliably stored all raw data in hour-long acquisitions at ultrahigh spectral rates.

Application Example #2 – (Bio-)Raman Spectroscopy

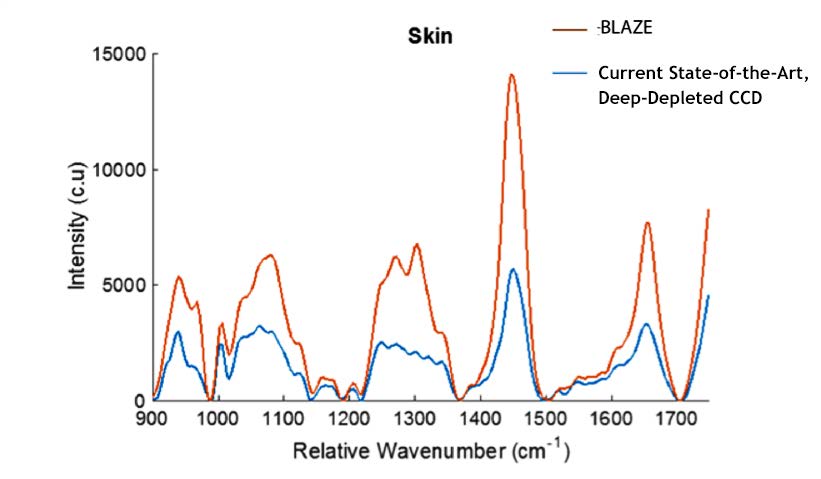

Raman spectroscopy is a useful non-invasive technique for cancer detection and other clinical research. The exceptional near-infrared quantum efficiency and fast spectral rates of BLAZE cameras allow quicker diagnostics and lower detection limits (see Figure 13). To minimize interference from auto-fluorescence and/or maximize penetration depth into tissue samples, researchers are increasingly focusing on near-infrared spectroscopic techniques, thus creating a strong need for low-noise detectors with high NIR quantum efficiency.

Application Example #3 – Materials Science / Nanotechnology / Two-Dimensional Materials Research

The discovery of graphene started the research field of two-dimensional materials, a class of materials possessing thicknesses of only a few layers (or even a single layer) of atoms. Materials like graphene, hexagonal boron nitride, and two-dimensional transition metal dichalcogenides (such as MoSe2 or WSe2) can be combined to form devices for optoelectronics and to study quantum optics in these materials. Detectors with the highest quantum efficiency in the NIR spectral region facilitate research by measuring the photoluminescence from these devices (see Figure 14).

Outstanding Utility

The groundbreaking combination of high near-infrared sensitivity and fast spectral rates afforded by BLAZE CCD cameras permits the acquisition of quantitative spectroscopic data previously unavailable or very difficult to obtain. In addition to being well suited for researchers working in the life sciences and materials sciences, these cameras are suitable for original

equipment manufacturers (OEMs) designing turnkey systems.

BLAZE cameras are fully compatible with all Teledyne Princeton Instruments spectrographs, including the SpectraPro HRS series and award-winning IsoPlane® imaging spectrographs (see Figure 15). Powerful 64-bit LightField software is available as an option.